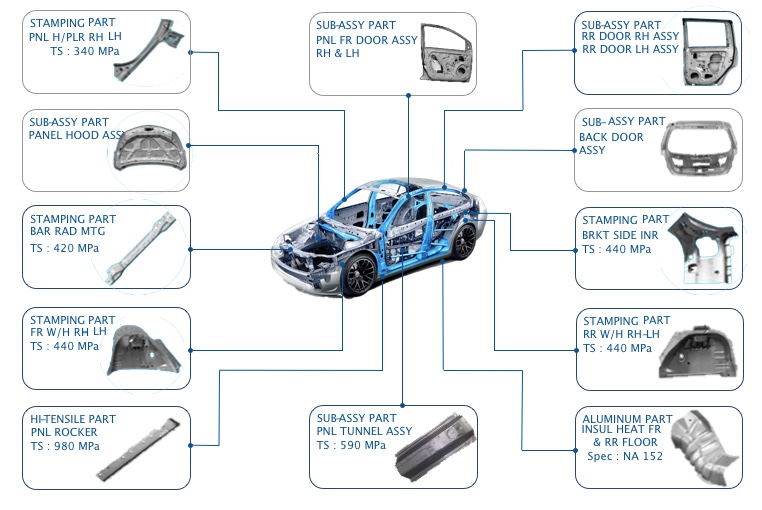

Current High Tensile Body Parts : 590 MPa Challenge : Ultra High Tensile > 980 MPa

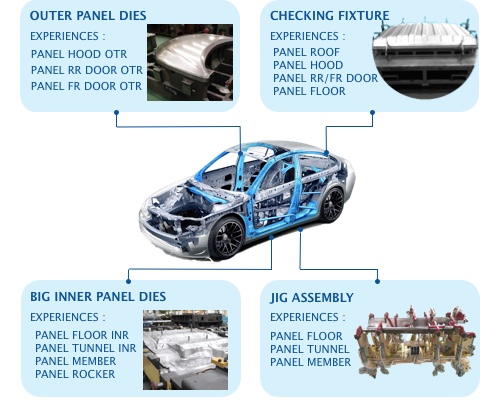

For the last 10 years, FTI had so much experience to develop the tooling for this bodypart. In development of high tensile bodypart tooling there are so many improvement or quality-up activities to achieve the target dimension, At least, we did 7 times of quality-up for each High Tensile Bodypart Tooling.

As the technology growing rapidly, FTI adopted so many the state of the art Computer Aided Engineering (CAE) to solve this situation and next challenge. Furthermore, nowadays bodypart use the ULTRA High Tensile Material, so that will affect directly to our development state.

To solve this challenge, FTI makes some strategies such as a Collaboration in CAE press simulation, CAD Modelling Modification based on CAE, and Die Compression Adjustment in the Press Machine. Collaboration in CAE press is done within our Customer, Coil Maker and also FTI Engineering. This collaboration is continued with CAD Data modification and also die compression adjustment in try out process.

Early 2020, FTI had already developed Ultra High Tensile from many customer. The development stages is helped by those strategies that we had done. This improvement in Ultra High Tensile Bodypart will encourage Indonesia Automotive Manufacturer to keep compete on an international level.